Story of Frank

This is Frank. He is the materials manager at his company, but the system they use costs an unnecessary amount of money and time. What Frank needs is a smarter, smoother and more cost-effective way to store, manage and access details.

At Smart Storing, we design and manufacture smart solutions that contribute to lower storage costs, the ability to pick details faster and a better ergonomic work environment.

Example 1

Smart Storing means you can store more things in less space. Warehouses and production areas often have pallet racks that contain a lot of air and unused storage space. With our products, you can fit more items in a smaller area. This frees up valuable floor space and increases your storage capacity. Why expand when you can use your premises in a smarter way?

Pull-out units, industrial modules such as our popular Industrial Offices and other extendable planes are a key feature of a modern, rational storage system.

Save on space & storage costs

Our products mean you can store more stuff in less space. This frees up valuable floor space and/or ncreases your storage capacity. Why expand when you can simply use your existing space in a smarter way?

Warehouses are often full of pallet racking which is holding mostly air. Storage units sized to suit your exact needs help to make your space work for you. Pull-out units are a key feature of a modern, rational storage system.

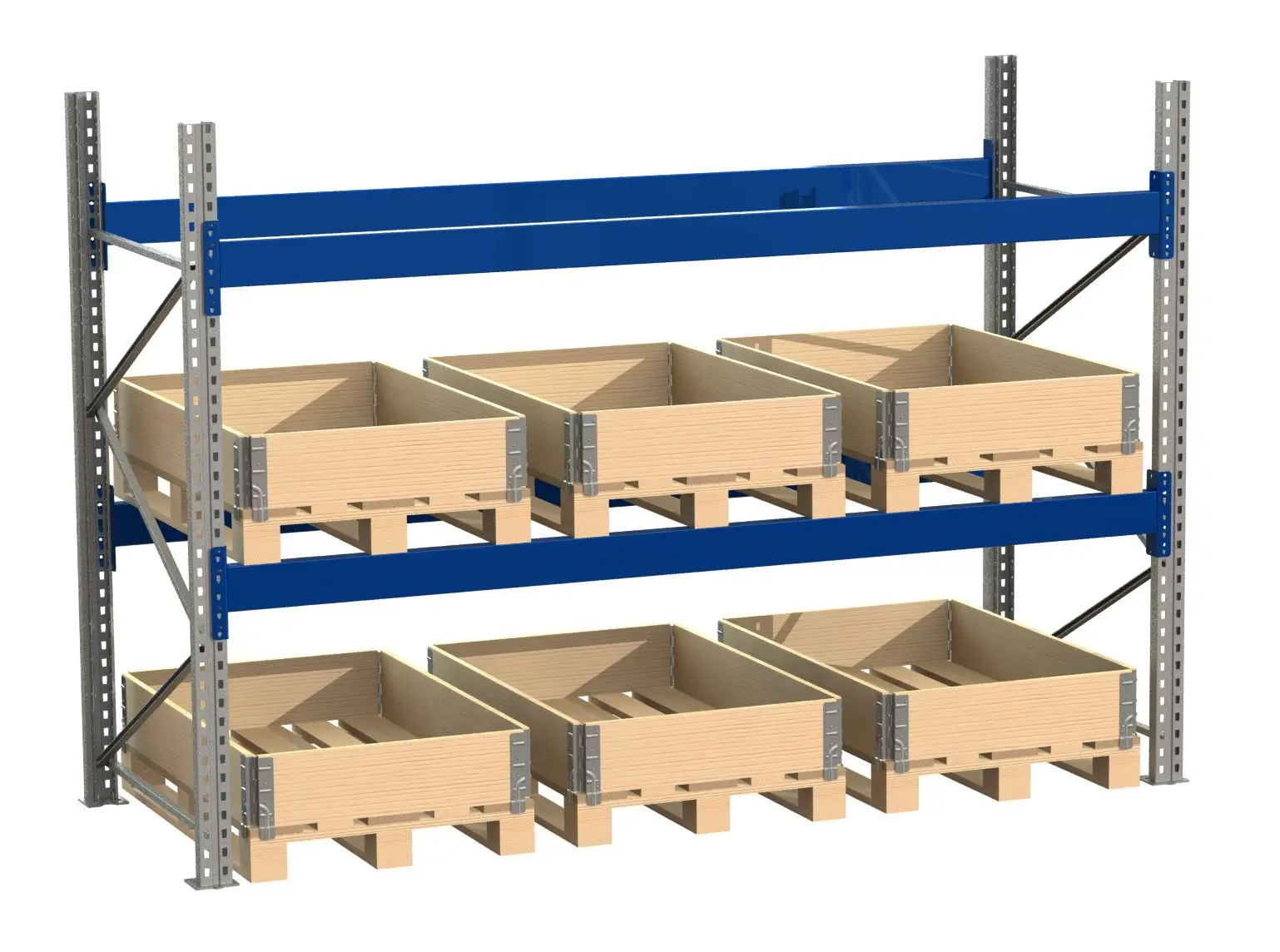

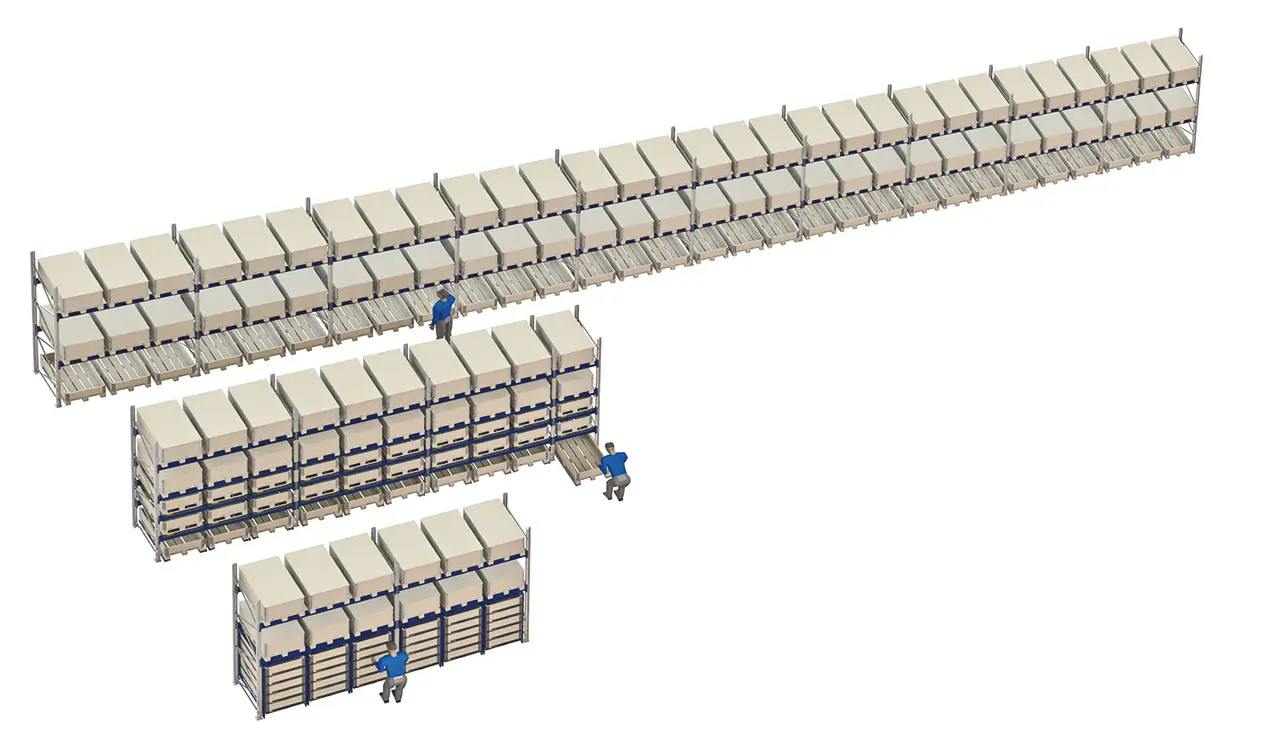

Standard pallet racking

Only 3 or 6 manual picking positions are possible, as you have to leave room for access to each layer.

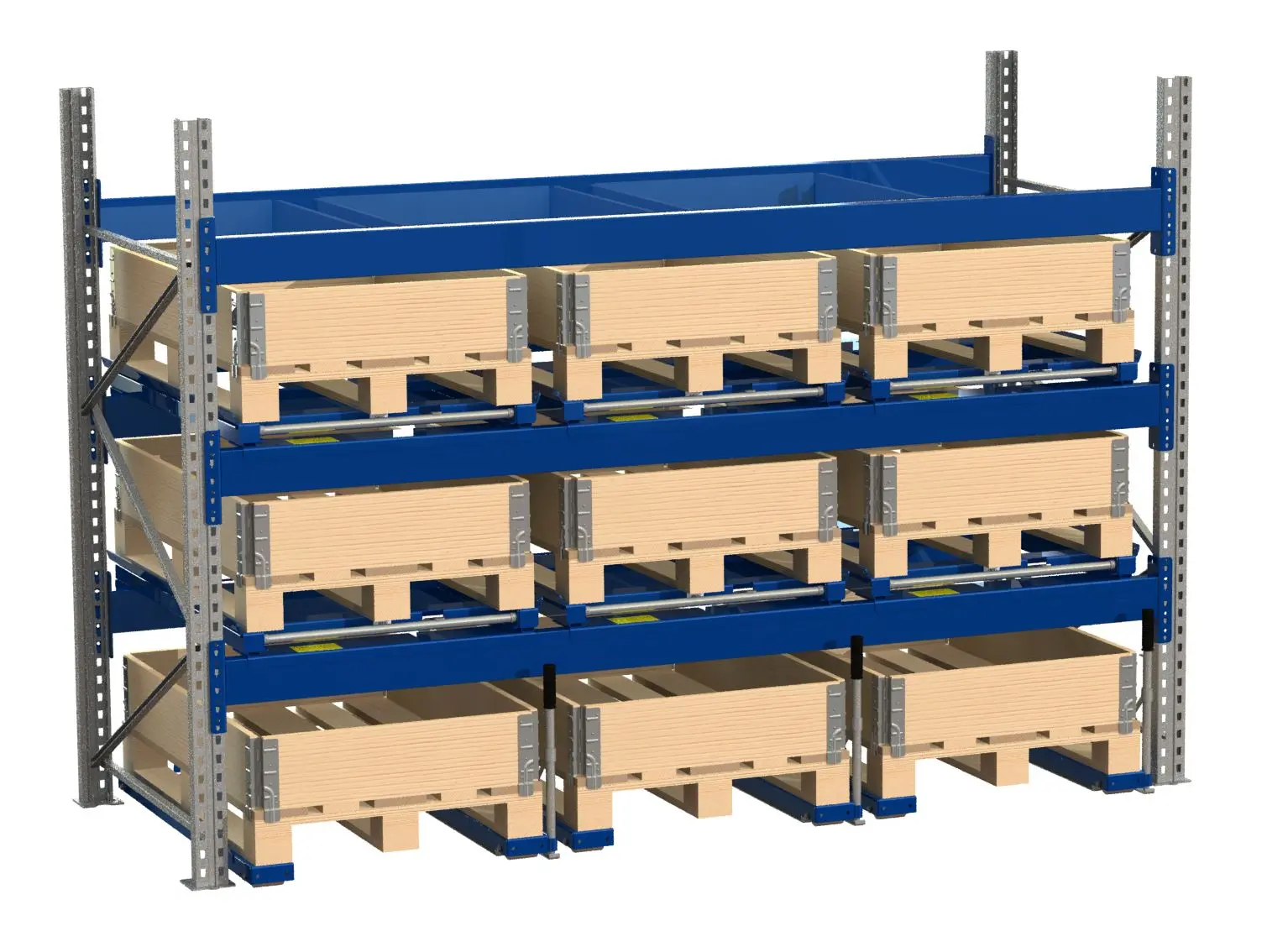

With Pull-out units

With an extra layer, you now have 9 picking positions – AND within arm´s reach.

With Compact Storage Units

With two extra shelves with pallet collars on the shelves, you now have 15 picking positions in the same space.

Example 2

Picking parts from pallet racks often takes a long time. If the pallet needs to be lifted down, there is a waiting time before a forklift driver can help – hardly an effective way of working. With pull-out units, a person can quickly pick details, even those that are far into the podium

Save on picking time

Picking items from pallet racking takes time. Often a fork lift must be used to lift a pallet down before components can be picked. That means the picker standing idle while he waits for a fork lift driver.

Then the fork lift driver sitting idle while he waits for the picker. Not an efficient use of manpower!

Pull-out units at a sensible height mean that a single worker can get immediate access to the goods or components needed. There’s no waiting if the fork lift is unavailable, and no waste of staff time.

Example 3

Since Smart Storing’s pull-out units allow parts to be easily picked manually by one person, forklift traffic is reduced. Less truck traffic means reduced labor, service and operating costs and in some cases the number of forklifts can also be reduced. Having good access to your inventory makes it easier to keep order and order. If you work with 5S, this is a prerequisite. When things are easy to find, less time is spent looking for them, fewer items are damaged, and order picking becomes more efficient.

Save on walking distance

Since the stacking density can be much higher with compact pull-out units, walking distances between items can also be reduced, saving even more time.

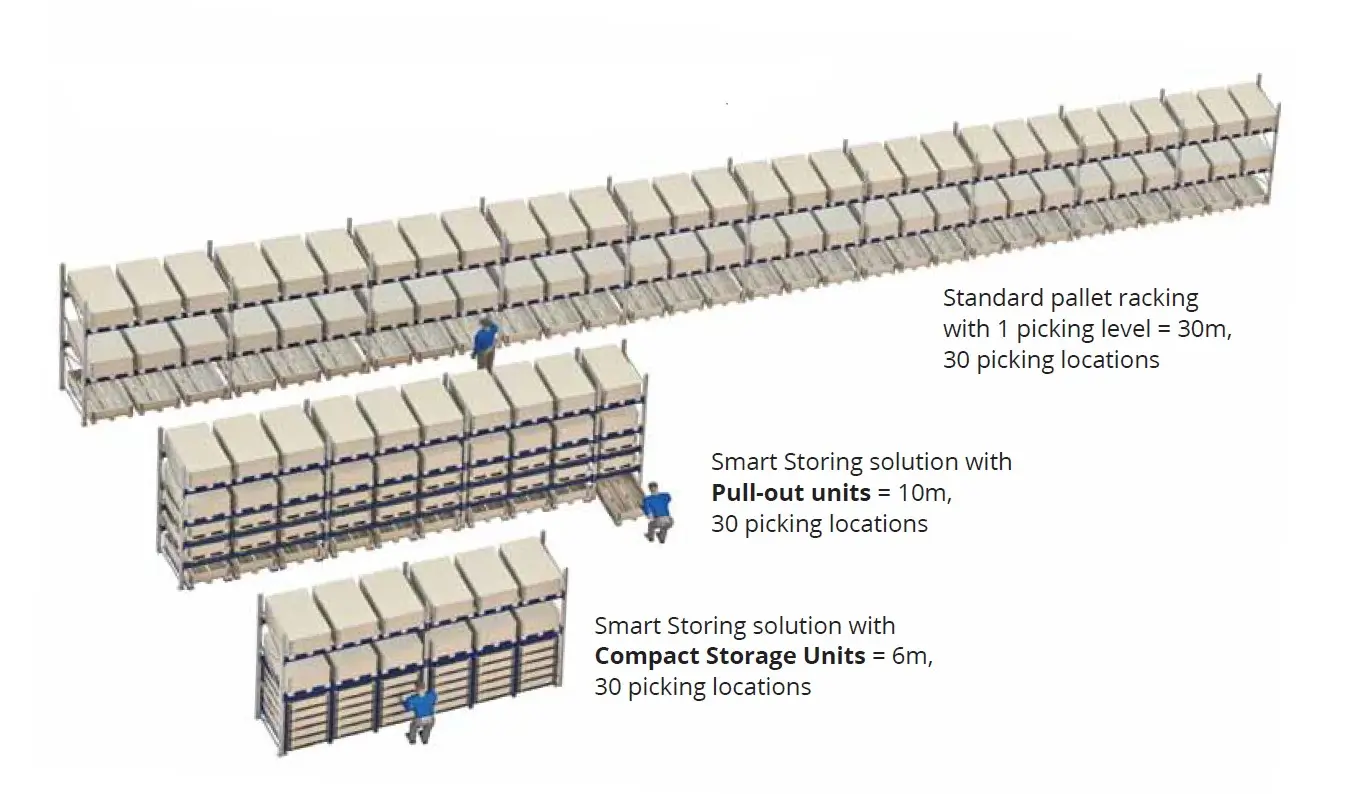

Reduces walking/picking distances

An example with 30 picking locations in different layouts.

Example 4

As the stock density can be much higher with compact pull-out units and industrial bureaus, the walking distance between items can also be reduced, saving even more time. This is particularly important in businesses that have a high picking frequency, such as e.g. distribution warehouse and E-commerce. See how Smart Storing reduces walking and picking distances: An example with 30 picking positions with different layouts

Save on internal transports

Fork Lifts. Less use of fork lifts means time saved, lower maintenance costs, a potential for a reduction in the number of trucks, and lower labour costs. That can only be good for your bottom line!

Having good access to your stores makes it easier to keep them organized, too.

Smart storage is more compact and picking is easier

When items are easy to find and to get hold of, less time is spent searching for them, fewer items get damaged and orderpicking is more efficient.

Example 5

We all need to take care of our staff, value their education and experience by making sure we stay healthy. Ergonomics is no longer a luxury – it is an important aspect for any business and has a big impact on overall profit margins. The single biggest cause of workplace injuries, regardless of industry, is injuries that result from lifting, pushing, pulling, holding or carrying something. Smart Storing’s warehouse solutions are designed so that employees do not have to use their bodies in a way that can lead to injuries. Easily accessible storage and picking systems lead to fewer stresses and injuries for staff. Often the staff is a company’s best asset. Save money by keeping it running smoothly!

Save on costs due to workplace injuries

It’s expensive to hire and fire. We all need to look after our workforces and to value their training and experience by keeping them healthy. Ergonomics is no longer a luxury – it’s an essential aspect of any business and has a major impact on overall profit margins.

The single biggest cause of workplace injuries

In any business, accounting for 25% of the direct costs, is ‘over-exertion’, defined as injuries caused by lifting, pushing, pulling, holding and carrying.

Bending, reaching, tripping, slipping and falling account for most of the rest. Smart storage solutions are designed to avoid the need for personnel to use their bodies in ways likely to lead to injury from these causes.