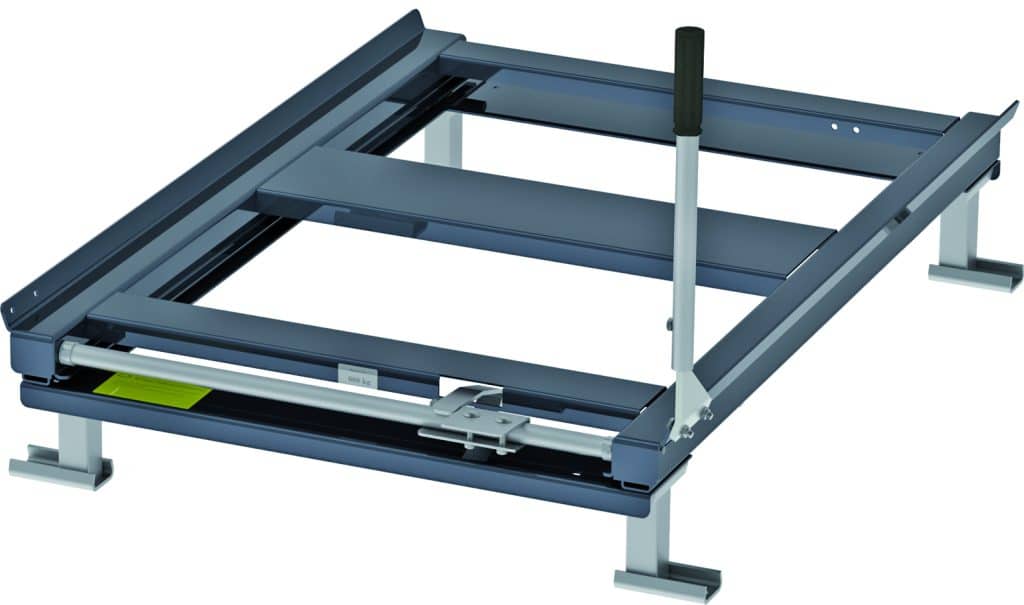

Floor-mounted pull-out units

Features

Click the buttons and read more about features

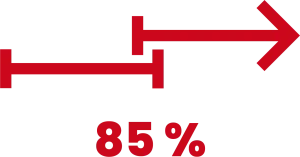

85%

PULL-OUT CAPACITY

CAN BE LOADED WITH:

– PALLET JACK

– STACKER

– FORKLIFT

AUTOMATICALLY LOCKS

in the retracted position

You have the OPTION to choose side handles, available with or without the Easy Action™ feature, foot-operated locks, and removable handles.

LOAD

CAPACITY

UP TO 1500 KG

GUIDE BEARINGS ensure that

THE UNITS STAY ALIGNED

when pulled out and can be

effortlessly pushed back in

Guide bearings also

PROTECT THE UNIT FROM

BEING DISLODGED in the

event of side impacts

LOW PROFILE!

Only 72 mm high. Easy to load

with a traditional pallet jack

Floor-mounted pull-out units fit under the rack and are compatible with almost any type of pallet racking, but can also be used as freestanding units.

They are fixed to the floor with bolts through the lower frames, which act as rails for the upper frames to slide out on bearings, and are supported by high quality pallet truck wheels at the front. Being able to pull the units out of the rack allows for safe and easy access to stored goods!Cost-saving ergonomics are a primary consideration with FM units, as with all Smart Storing designs. Each model uses the right sizes and numbers of quality ball bearings, so they’re strong, reliable and easy to slide in and out. Guide rails ensure the units stay in line when pulled out, and can be pushed back in without effort.

A safety latch is automatically engaged when the unit is in the rack. This prevents the unit from being unintentionally pushed out from the other side of the rack. (This feature is especially important when using rear loaded units or units placed in a double rack, where they can be hit from behind when loading the opposite unit).

Video

Help choosing the right one

Find out the true weight of your palletized goods to select the right load capacity. Load capacity refers to the load distributed over the entire surface. Choose the pallet size and from which direction you want to handle the goods, short side or long side. Choose how you load; from the back or front. Finally, select the pull-out capacity. What you choose here depends on how the goods will be handled and how large they are.

Load Capacity

Loading

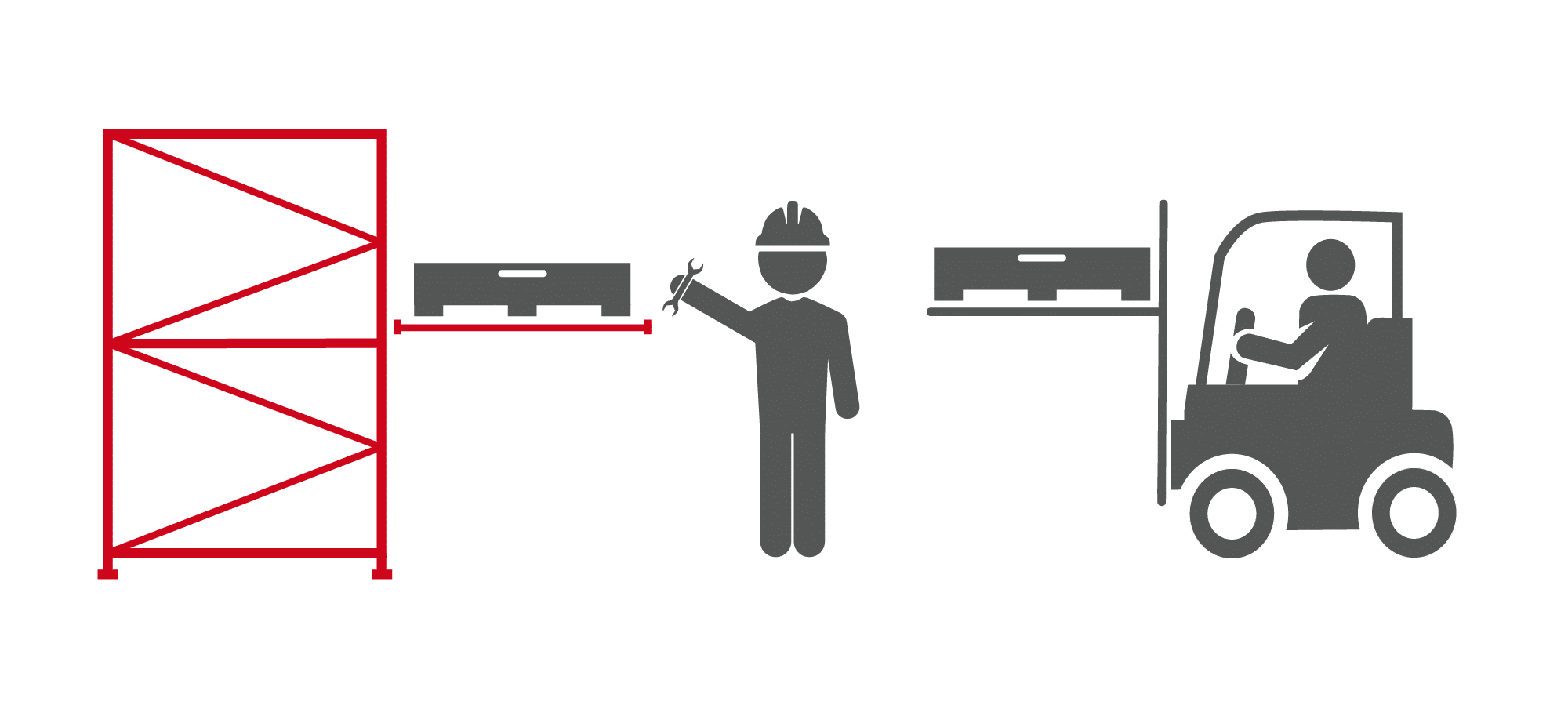

FRONT-LOADED

Loading and picking from the same side

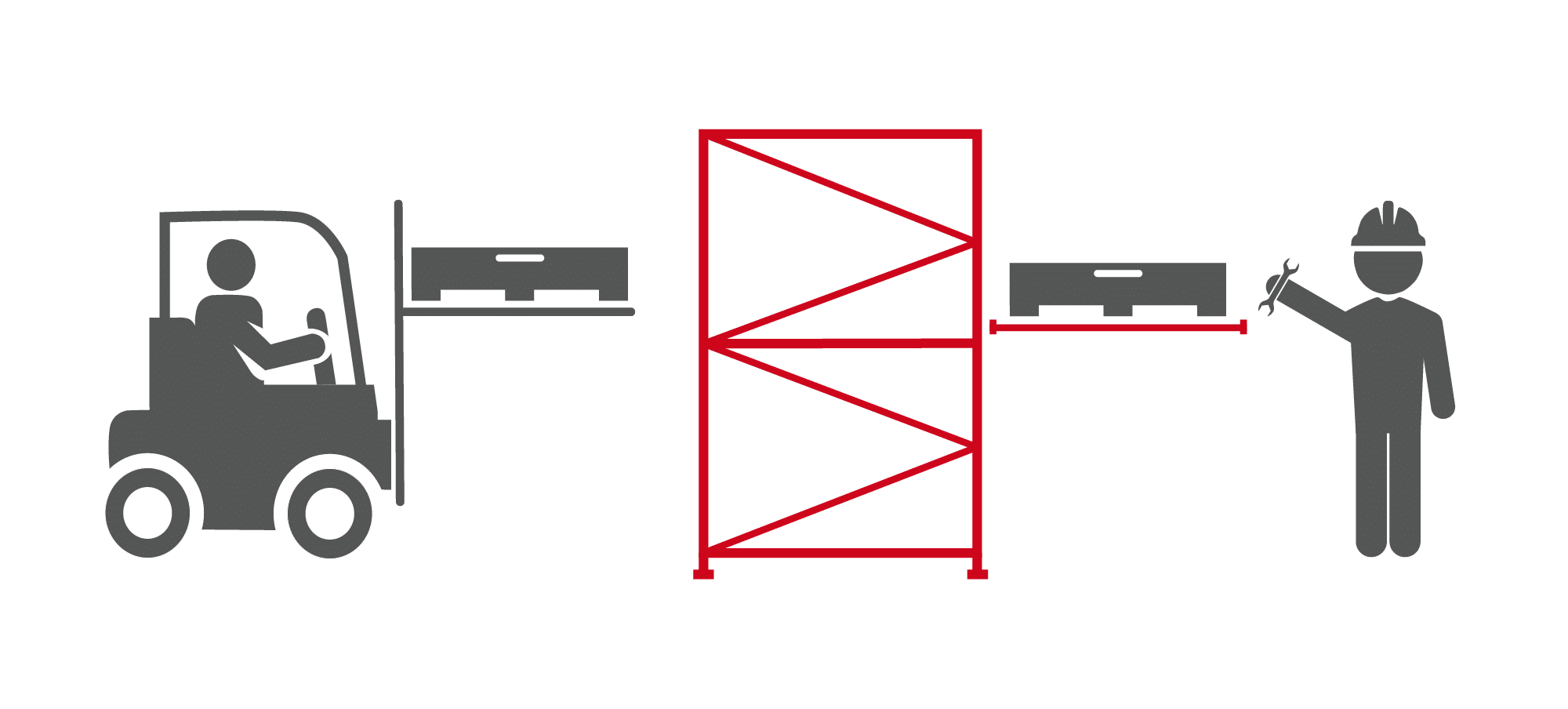

REAR-LOADED

Loading from the back

Front loading

Rear loading

For when you load from the back of the pallet rack and pick from the front

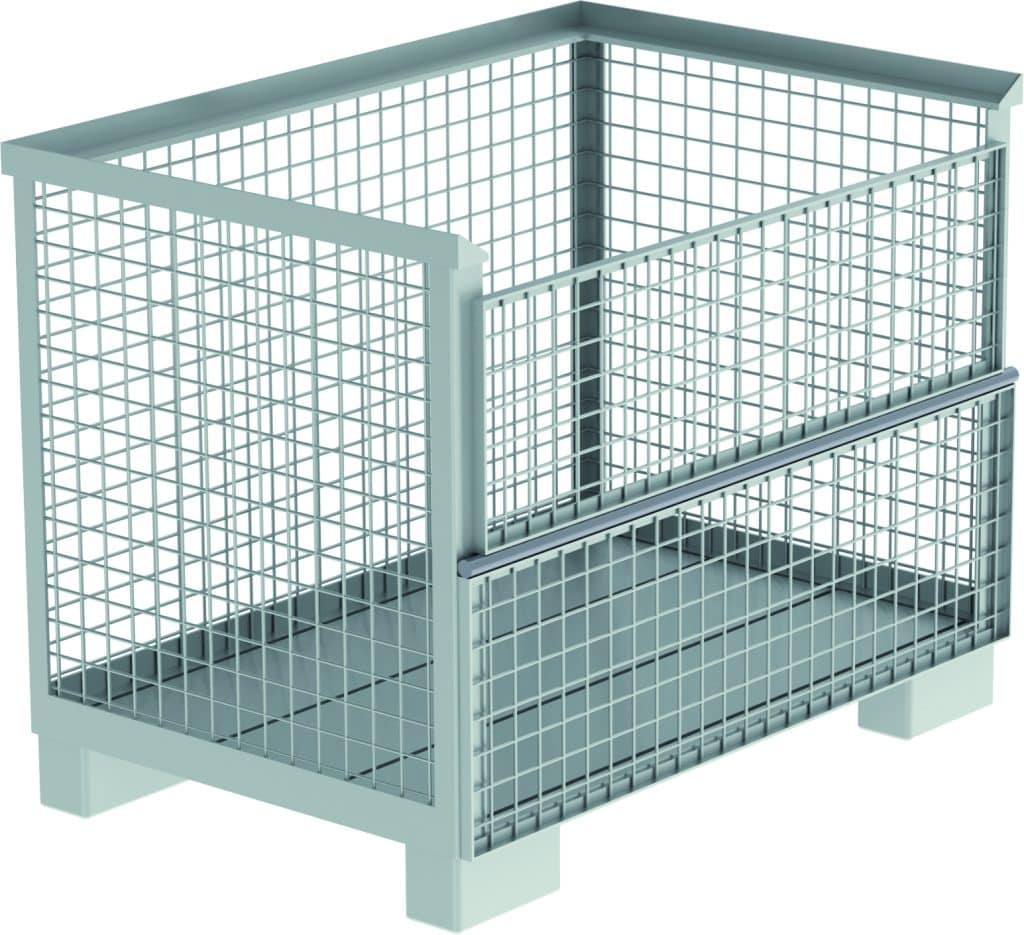

Heavy metal unit (HMU)

Features steel corner plates with raised edges both to ensure the containers stay in place and to strenghten the unit to accept point loads at the corner

Pallet Size and orientation

It doesn’t matter what size pallets you use or which way round you handle them.

– Smart Storing has the pull-out unit to fit with a fork lift truck!

With Floor-mounted units, you need to allow room for the pallet forks when loading units. We offer several designs, for front or rear loading.

Floor-mounted units

For more information about each individual product, click on the article number.

| Pallet Size | Loading | Orientation | 800 kg | 1000 kg | 1200 kg | 1500 kg |

|---|---|---|---|---|---|---|

| EUR | Front Loaded | Short-side Handled | 13 801 | 13 1001 | 13 1201 | 13 1501 |

| EUR | Rear-Loaded | Short-side Handled | 13 802 | 13 1002 | 13 1202 | 13 1502 |

| EUR-L | Front Loaded | Long-side Handled | 13 805 | 13 1005 | 13 1205 | 13 1505 |

| EUR-L | Rear-Loaded | Long-side Handled | 13 806 | 13 1006 | 13 1206 | 13 1506 |

| FIN | Front Loaded | Short-side Handled | 13 803 | 13 1003 | 13 1203 | 13 1503 |

| FIN | Rear-Loaded | Short-side Handled | 13 804 | 13 1004 | 13 1204 | 13 1504 |

| FIN-L | Front Loaded | Long-side Handled | 13 807 | 13 1007 | 13 1207 | 13 1507 |

| FIN-L | Rear-Loaded | Long-side Handled | 13 808 | 13 1008 | 13 1208 | 13 1508 |

| HMU (wire mesh Container) | Front-Loaded | Short-side Handled | 13 809 | 13 1009 | 13 1209 | – |

| HMU (wire mesh Container) | Rear Loaded | Short-side Handled | 13 810 | 13 1010 | 13 1210 | – |

| HMU-L (wire mesh Container) | Front-Loaded | Long-side Handled | 13 811 | 13 1011 | 13 1211 | – |

| HMU-L (wire mesh Container) | Rear Loaded | Long-side Handled | 13 812 | 13 1012 | 13 1212 | – |

Handles for floor-mounted units

Orientation

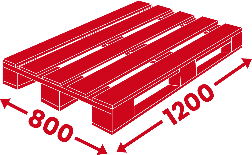

EUR-pallet

HMU-L

Short-side handling

1200 mm x 800 mm (LxW)

HMU-L

Long-side handling

800 mm x 1200 mm (LxW)

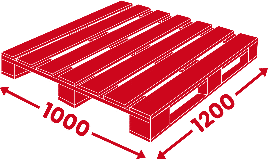

FIN-/ CHEP-pallet

HMU-L

Short-side handling

1200 mm x 1000 mm (LxW)

FIN-L

Long-side handling

1000 mm x 1200 mm (LxW)

Wire mesh container

HMU-L

Short-side handling

1200 mm x 800 mm (LxW)

HMU-L

Long-side handling

800 mm x 1200 mm (LxW)

| ART. NO. | SPECIFICATION |

|---|---|

| 13-15 | Standard handle, 500 mm |

| 13-17 | Standard handle, 700 mm |

| 13-19 | Standard handle, 900 mm |

| 13-25 | Easy Action™-handle, 500 mm |

| 13-27 | Easy Action™-handle, 700 mm |

| 13-29 | Easy Action™-handle, 900 mm |

| 13-35 | Detachable handle including foot lock, 500 mm |

| 13-37 | Detachable handle including foot lock, 700 mm |

| 13-39 | Detachable handle including foot lock, 900 mm |

| 13-4 | Foot lock |

FOOT-OPERATED RELEASE CATCH

Used with, for example, HMU models when a side handle is not suitable. Delivered complete with floor stop.

REMOVABLE HANDLE

Suitable if you have material protruding beyond the pallet, and the handle gets in the way during loading or unloading. Delivered complete with floor stop and foot lock.

STANDARD HANDLE

A handle with a built-in locking function that keeps the floor-mounted model in place when you load it. Delivered complete with a floor stop.

EASY ACTION™ -HANDLE

A clever mechanism enables the handle to function like a lever, reducing the force required to extract a heavy pallet. WORKS LIKE A LEVER for best ergonomics!

Floor mounted pull-out units | Product range

Floor mounted pull-out units | Accessories

Steel shelf panels

An accessory that covers the top of the pull-out unit. With this, you can store plastic bins, cardboard boxes, production tooling or loose items. It’s also possible to store pallets directly on the steel shelf panel, providing flexible storage. Material: Galvanized steel.

| ART. NO. | SPECIFICATION |

|---|---|

| 13 180-0 | Steel shelf panel for short-side handled EUR unit |

| 13 180-6 | Steel shelf panel for long-side handled EUR unit |

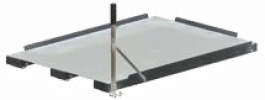

Extra pallet support bar

To enhance the load-bearing capacity, add a pallet support bar that includes an extra wheel. This accessory provides crucial support for the pallet’s center skid during high loads, particularly beneficial when using plastic pallets or when placing a steel shelf panel on top.

Antiskid tape

Four pieces of self-adhesive tape at each corner. The tape has a rough surface which grips the pallet and prevents it from sliding around when empty or lightly loaded.

| ART. NO. | SPECIFICATION |

|---|---|

| 11 002-0 | Set of 4 pcs |

Upright protectors Smart 400

Standard upright protectors are often bulky and might limit the inside width so floor-mounted pull-out units will not fit. The slim upright protector Smart 400 will solve this problem! Height 400 mm, depth 490 mm. Powder coated yellow.

| ART. NO. | SPECIFICATION |

|---|---|

| 13 401249 | Width 120 mm (for post width 80 – 100 mm) |

| 13 401349 | Width 130 mm (for post width 90 – 110 mm) |

| 13 401549 | Width 150 mm (for post width 110 – 130 mm) |

Pallet collar kit

By storing small items directly on your floor-mounted pull-out unit, without a pallet, you can save even more space in height. The pallet collar can be complemented with pallet collar dividers. See page 114 for Pallet Accessories.

| ART. NO. | SPECIFICATION |

|---|---|

| 13 180-80 | Pallet collar with cut brackets, steel shelf panel and extra support bar |

Installation template

Steel plate with handles and predrilled holes. This accessory is a huge time saver when drilling the holes in the floor to receive the expanding bolts to secure FM units. Simply line up as many templates as you need – either 2 or 3 depending on how many pallet places there are between the uprights in your rack – and mark the holes easily and accurately – no need to measure!

| ART. NO. | SPECIFICATION |

|---|---|

| 13-MP | Installation template, specify the article number of the floor model to be used for the template when ordering. |

CONVERT A BEAM-MOUNTED UNIT INTO A FLOOR-MOUNTED MODEL

- – If the floor surface is too uneven for the wheels.

– If the floor is not level.

– If you desire pull-out units to be positioned at a higher level to enhance picking ergonomics.

– If you require 100% pull-out capacity, even though 85% is often sufficient for full access.