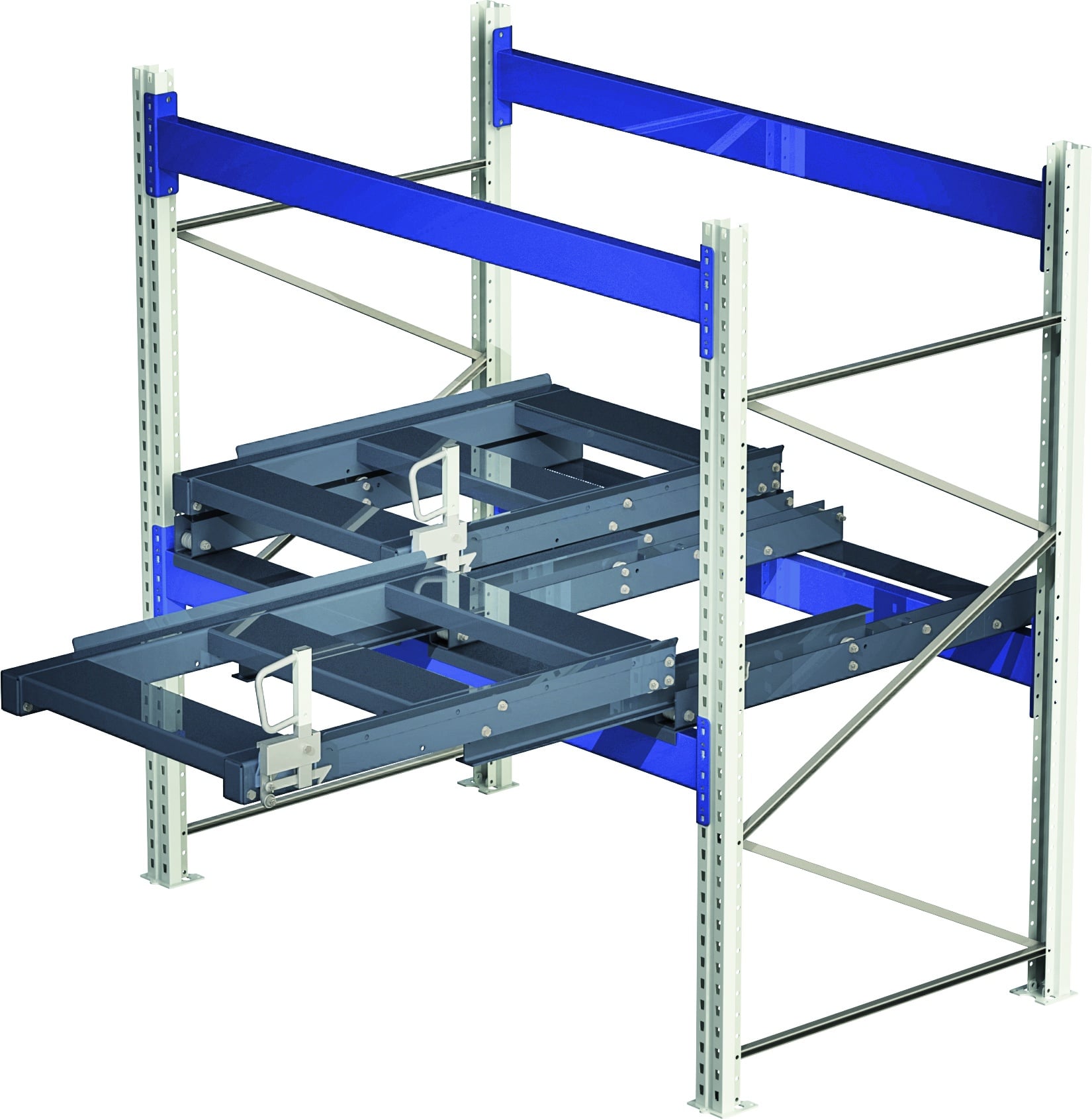

Beam-mounted pull-out units

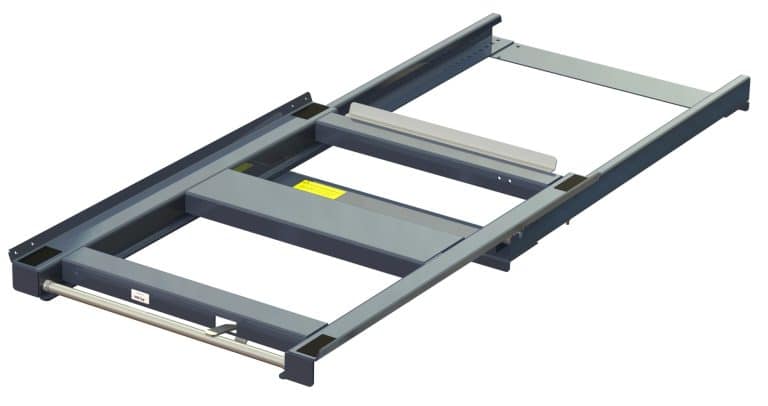

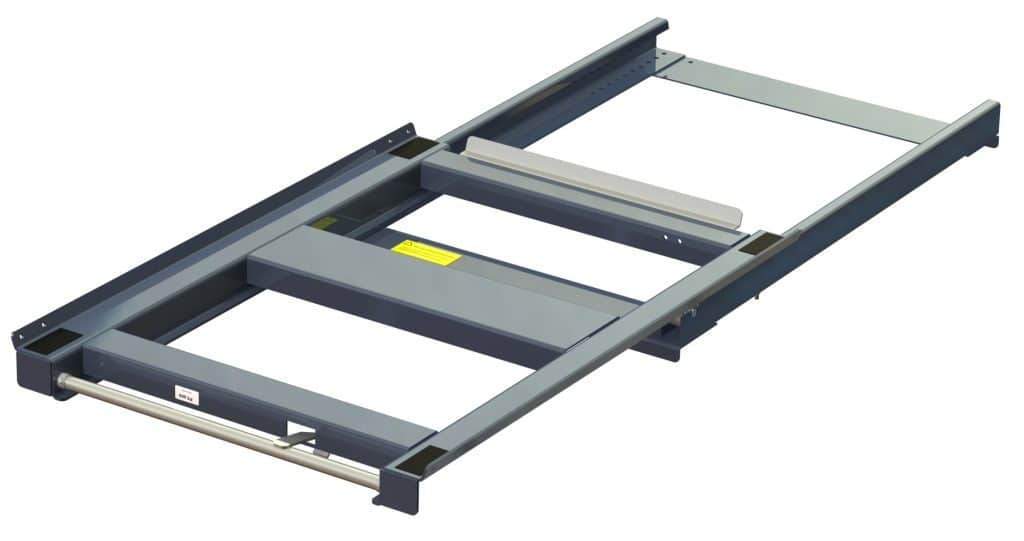

Our pull-out units are supplied ready assembled and fully tested.

Features

Click the buttons and read more about features

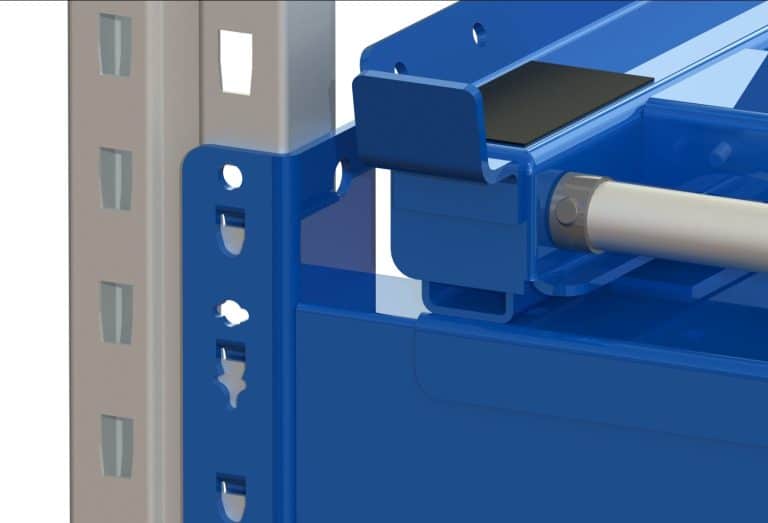

COMPATIBLE with nearly all pallet racks available on the market

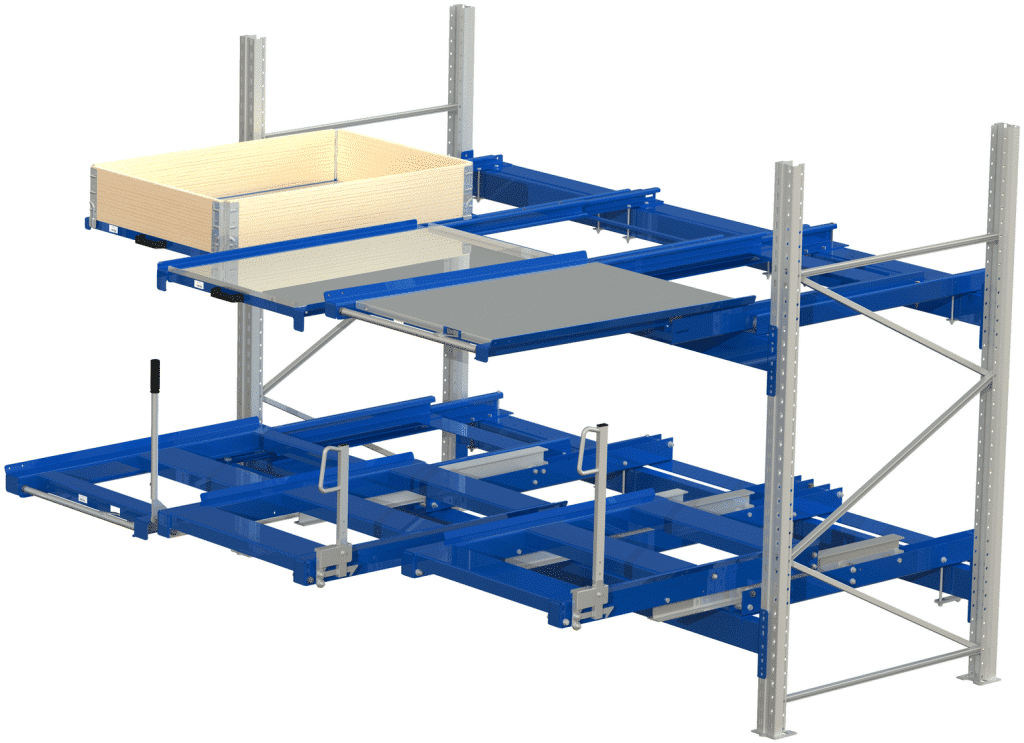

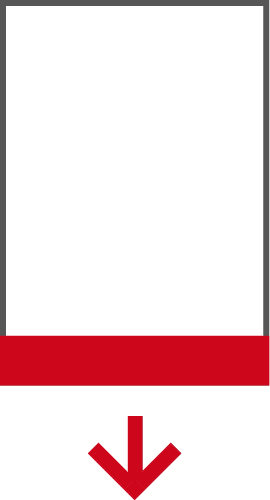

UNITS WITH AN 'OPEN FRAME' are designed for Pallets

100% PULL-OUT CAPCITY

1-WAY UNIT

100% PULL-OUT CAPCITY

1-WAY UNIT

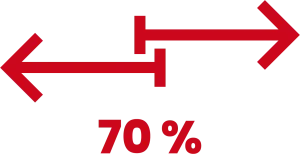

70% PULL-OUT CAPACITY

1-WAY UNIT

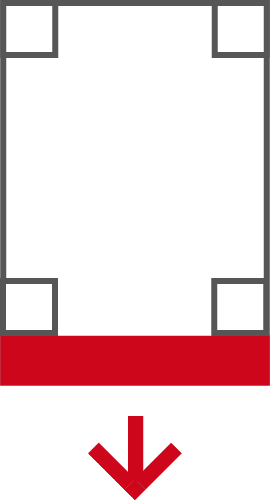

2-WAY UNIT

70% PULL-OUT CAPACITY

1-WAY UNIT

2-WAY UNIT UNITS WITH STEEL SHELF PANELS are well-suited for storing plastic bins, cardboard boxes, and loose objects

Use STANDARD pallet collars and turn your pull-out unit into a practical drawer

Our pull-out units are supplied ready

assembled and fully tested.

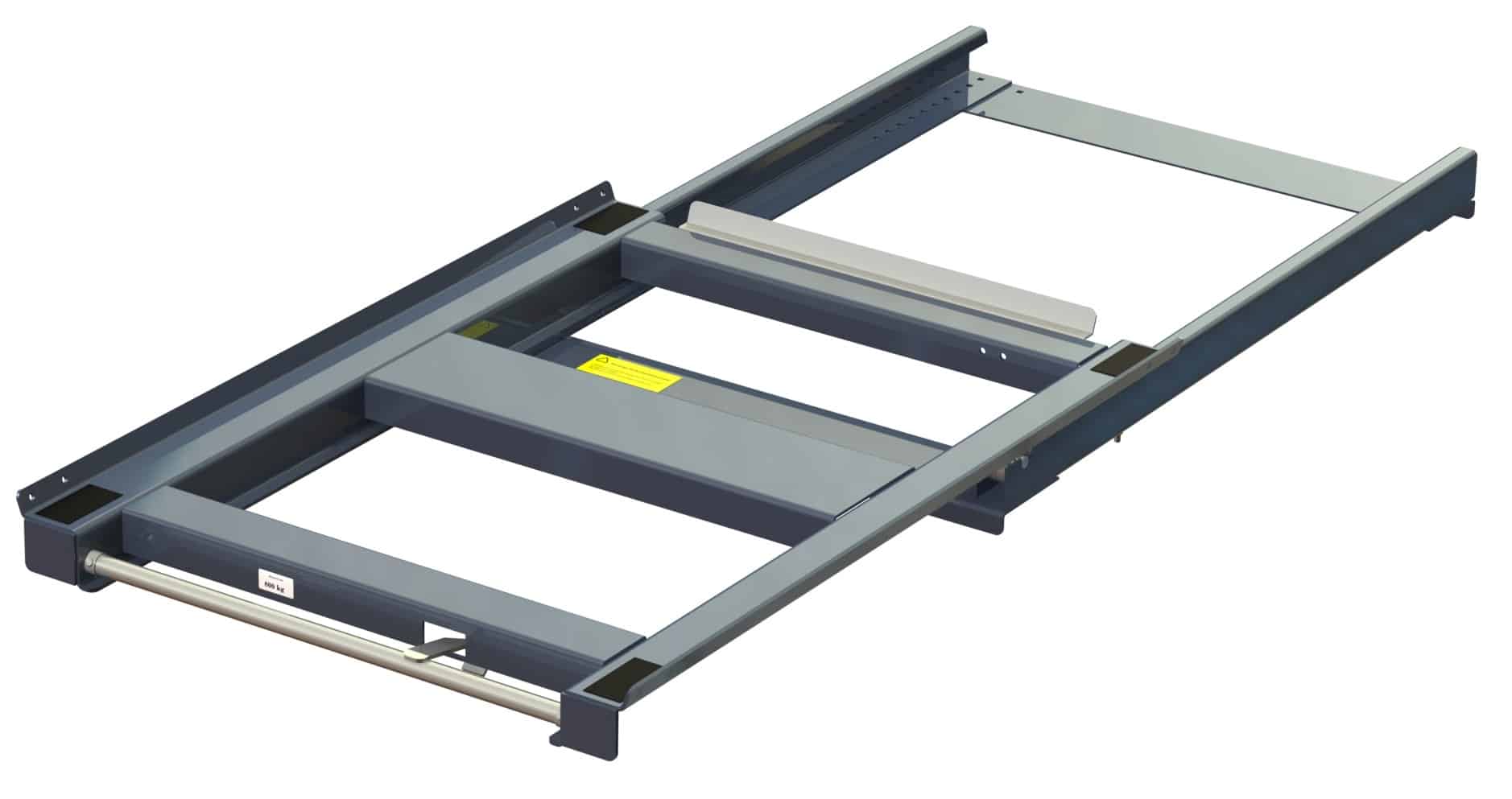

Beam-mounted pull-out units are installed on the beams within a pallet rack. The unit’s lower frame is securely attached to the rear load beam, while the upper frame runs on the lower frame with the help of ball bearings. Typically, pallets are handled on these units, but the addition of a steel shelf panel allows for the storage of smaller items like plastic bins or cardboard boxes directly on the unit.

Beam-mounted units are available in a range of capacities up to 1500kg and in a variety of formats to suit your requirements. They can cater for all pallet sizes and types (wood, steel, plastic), front or rear loading at the pallet rack, short or long-side handling, as well as for pallet collars with dividers, containers, bins and loose storage.

In addition to units for pallet handling, there are units for manually handled materials such as boxes and cartons.

Help choosing the right one

Load Capacity

Pallet size & orientation

EUR

Short-side handled pallet 800 x 1200 mm (W x L)

FIN

Short-side handled pallet 1000 x 1200 mm (W x L)

HMU

Short-side handled with reinforced corners securing a wire mesh container 800 x 1200 mm (W x D)

EUR-L

Long-side handled pall

1200 x 800 mm (W x L)

FIN-L

Long-side handled pall

1200 x 1000 mm (W x L)

HMU-L

Long-side handled with reinforced corners securing a wire mesh container 1200 x 800 mm (W x D)

Loading

FRONT-LOADED

Loading and picking from the same side

REAR-LOADED

Loading from the back

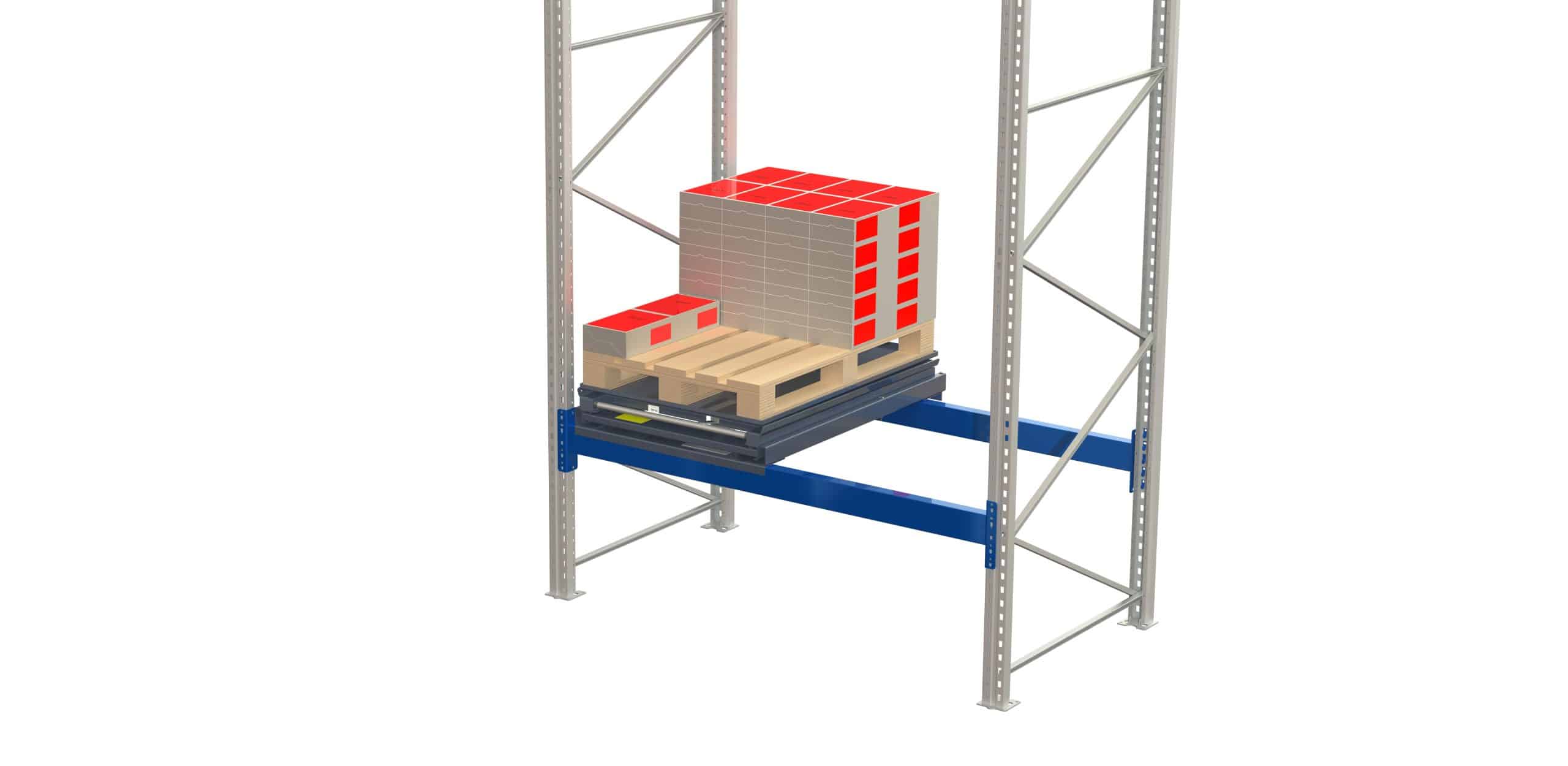

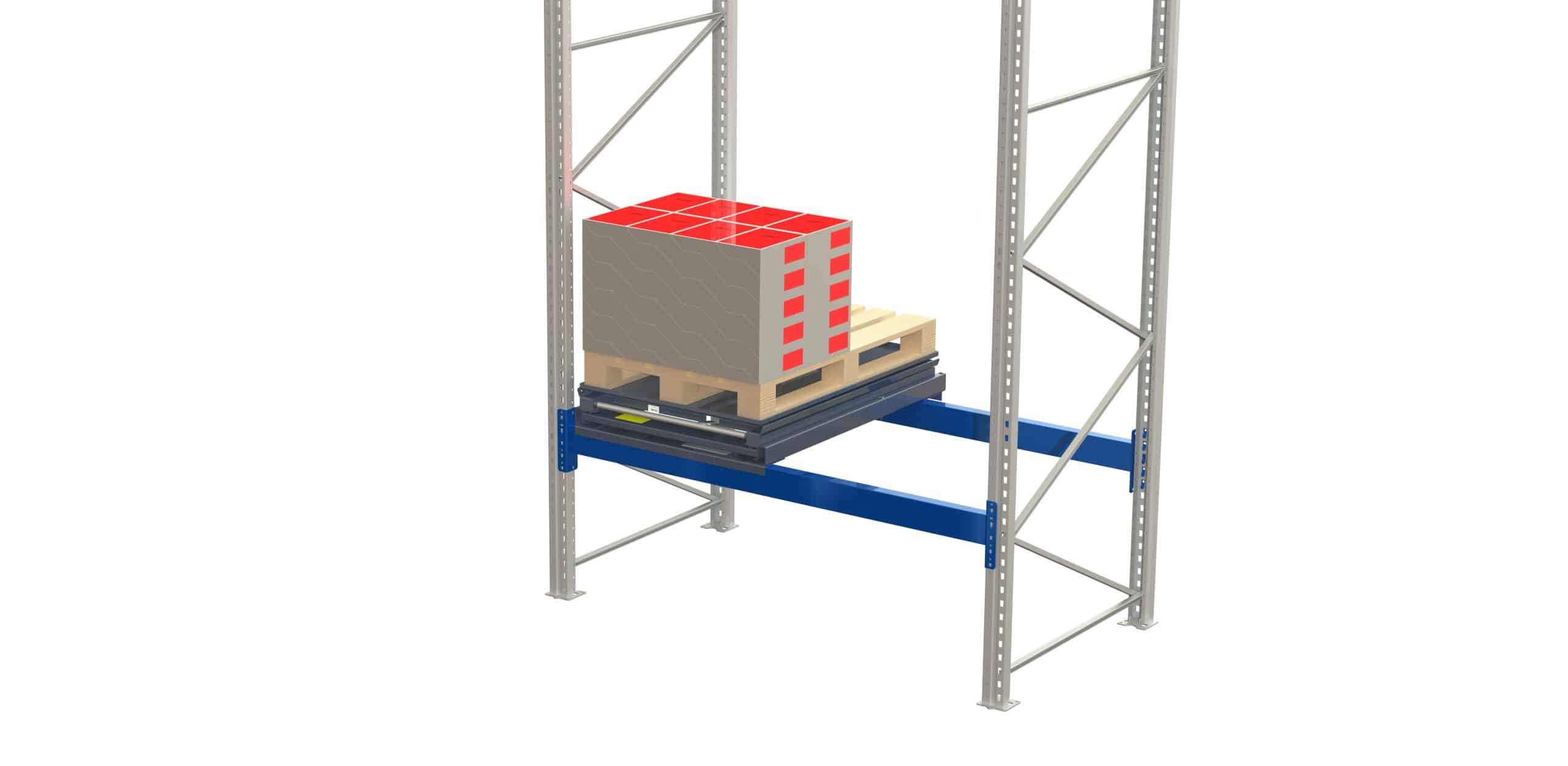

Pull-out capacity

70% extension one-way

70% PULL-OUT CAPACITY

In most cases, a 70% extension is

adequate to access all goods.

100% extension one-way

100% PULL-OUT CAPACITY

100% extension offer full access to

small goods also when placed far back on a shelf or pallet. It’s also perfect when handling heavy goods with an overhead crane.

70% extension two-way

70% PULL-OUT CAPACITY

2-WAY UNIT

The unit can be pulled out in two

directions, allowing access from both sides of the pallet rack

Beam-mounted pull-out unit with 70% pull-out capacity and 300 - 1500 kg load capacity

Beam-mounted 70% pull-out capacity

| Pallet Size | Loading | Orientation |

|---|---|---|

| EUR | Front Loaded | Short-side Handled |

| EUR | Rear-Loaded | Short-side Handled |

| EUR-L | Front Loaded | Long-side Handled |

| EUR-L | Rear-Loaded | Long-side Handled |

| FIN | Front Loaded | Short-side Handled |

| FIN | Rear-Loaded | Short-side Handled |

| FIN-L | Front Loaded | Long-side Handled |

| FIN-L | Rear-Loaded | Long-side Handled |

| HMU (wire mesh Container) | Front-Loaded | Short-side Handled |

| HMU (wire mesh Container) | Rear Loaded | Short-side Handled |

| HMU-L (wire mesh Container) | Front-Loaded | Long-side Handled |

| HMU-L (wire mesh Container) | Rear Loaded | Long-side Handled |

| EUR 1/2 Pallet | Front-Loaded | Front-side Handled |

| 300 kg | 600 kg | 800 kg | 1000 kg | 1200 kg | 1500 kg |

|---|---|---|---|---|---|

| 11 301-0 | 11 601-0 | 11 801-0 | 11 1001-0 | 11 1201-0 | 11 1501-0 |

| 11 302-0 | 11 602-0 | 11 802-0 | 11 1002-0 | 11 1202-0 | 11 1502-0 |

| – | 11 605-0 | 11 805-0 | 11 1005-0 | – | – |

| – | 11 606-0 | 11 806-0 | 11 1006-0 | – | – |

| – | 11 603-0 | 11 803-0 | 11 1003-0 | 11 1203-0 | 11 1503-0 |

| – | 11 604-0 | 11 804-0 | 11 1004-0 | 11 1204-0 | 11 1504-0 |

| – | 11 607-0 | 11 807-0 | 11 1007-0 | – | – |

| – | 11 608-0 | 11 808-0 | 11 1008-0 | – | – |

| – | – | 11 809-0 | 11 1009-0 | 11 1209-0 | 11 1509-0 |

| – | – | 11 810-0 | 11 1010-0 | 11 1210-0 | 11 1510-0 |

| – | – | 11 811-0 | 11 1011-0 | 11 1211-0 | 11 1511-0 |

| – | – | 11 812-0 | 11 1012-0 | 11 1212-0 | 11 1512-0 |

| – | 11 613-0 | – | – | – | – |

Beam-mounted pull-out unit with 100% pull-out capacity and 300 - 1000 kg load capacity

Beam-mounted 100% pull-out capacity

For more information about each individual product, click on the article number.

| Pallet Size | Loading | Orientation |

|---|---|---|

| EUR | Front Loaded | Short-side Handled |

| EUR | Rear-Loaded | Short-side Handled |

| EUR-L | Front Loaded | Long-side Handled |

| EUR-L | Rear-Loaded | Long-side Handled |

| FIN | Front Loaded | Short-side Handled |

| FIN | Rear-Loaded | Short-side Handled |

| FIN-L | Front Loaded | Long-side Handled |

| FIN-L | Rear-Loaded | Long-side Handled |

| HMU (wire mesh Container) | Front-Loaded | Short-side Handled |

| HMU (wire mesh Container) | Rear Loaded | Short-side Handled |

| HMU-L (wire mesh Container) | Front-Loaded | Long-side Handled |

| HMU-L (wire mesh Container) | Rear Loaded | Long-side Handled |

| EUR 1/2 Pallet | Front-Loaded | Front-side Handled |

Video

Rotable pull-out unit

In warehouse operations, especially in food distribution, the rapid picking of goods is crucial. Pickers reach as far as possible onto the pallet, and when their reach is exhausted, turning the pallet becomes necessary. Traditionally, this involved using a forklift to bring down the pallet, driving the forklift around to the opposite side, and then lifting the pallet back up.

Now, with Smart Storing’s beam-mounted pull-out unit R1, flipping the pallet can be achieved in a single motion. This efficient capability saves a significant amount of time.

-

PULL OUT

-

ROTATE

-

PUSH IN

We help you find the right solutions!

Introducing our Rotable pull-out unit – With its smooth rotation mechanism, you can effortlessly reach every item without the need for a forklift. Beam-mounted, front or rear-loaded and short-side handled.

A patent pending innovation by Smart Storing!

Pick from the pallet as far as you can reach

Pull out and turn the pallet.

Push back in and continue to pick!

Accessories for Beam-mounted units

Click the buttons and read more about accessories

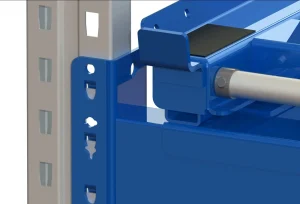

A pull-out unit locking system avoids the danger of the cross-beam

A pull-out unit locking system avoids the danger of the cross-beam

being overloaded. The lock is available for two, three or four pallet-width

bays and locks one section at the time. When one unit is pulled out, the

others are locked. Normally this lock is placed at the back. We also have

a lock that is placed under the unit; this is typically used when there isn’t

enough room behind, for example if you have double pallet racks, or if

you load from the rear.

Rear pallet stop

Rear pallet stop

An angle profile which can be fitted to the back of the unit to stop the pallet sliding too far back when the unit is pushed in. Supplied ready fitted to unit.

Anti-skid tape

4 pieces of self-adhesive anti-skid tape,

to be stuck to each corner to stop the

pallet moving around when empty or

very lightly loaded.

Anti-skid tape

4 pieces of self-adhesive anti-skid tape,

to be stuck to each corner to stop the

pallet moving around when empty or

very lightly loaded.  Feet for BM unit

Feet for BM unit

For mounting BM units off the floor. Two sizes, for up to 800kg units and up

to 1000kg units. Height 150mm, galvanized steel.

Foot-operated lock release catch Recommended for units installed close to floor level.

Foot-operated lock release catch Recommended for units installed close to floor level.

Floor mounting profiles

Floor mounting profiles

For mounting BM units close to the floor. Three versions,

for short-side and long-side forward handling up to

1000kg, and for short-side handling up to 1500kg.

Height 35mm, galvanized steel.

Lock in extended position

Lock in extended position

Sometimes you want to lock the unit when it´s pulled out, for example while picking

or loading goods. This lock is also useful with narrow aisles, so that when the unit is

fully pulled out you can load a pallet from the side.

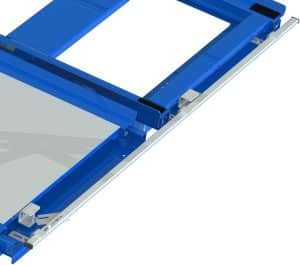

Steel shelf panel

This accessory covers the top of the

pull-out unit so that smaller items such as

plastic bins or cartons can’t slip through.

You can still use the unit for pallets, so you

have fully flexible storage.

Material: Galvanized mild steel

Front pallet stop

A pair of steel plates for mounting either side of the unit at the front, acts as a safety stop when loading a pallet from the rear.

Front pallet stop

A pair of steel plates for mounting either side of the unit at the front, acts as a safety stop when loading a pallet from the rear.

| ART.NO | Specification.NO |

|---|---|

| 11 001-40 | Front edge stops left & right for beam-mounted unit |

Handles for beam-mounted units

The units have integrated horizontal locking handles. Side handles are recommended for BM pull-out units when they are fitted in the lower and mid-range of picking heights, to save bending. Two types are available, Standard and Easy Action™ (EA). Both

types of handle are available in a range of lengths.

Standard handles are simply something to pull on, ideal when a unit is fitted on the

bottom two tiers of the racking. Suitable for all units below 1000kg rating. Supplied separately for fitting by customer.

Easy Action™- (EA) handles use a lever mechanism mounted on ball-bearings to greatly increase the operator’s mechanical advantage. They make it effortless to slide out even a heavily loaded unit. Comes complete mounted on selected unit.

There are three choices to pull out the shelf. The choice of 70% or 100% extension capacity depends mainly on whether or not it’s easy to pick your items from the back of the unit. The choice of one- or two-way action depends on whether you want to load and pick from one side only or to have equal access from both sides..

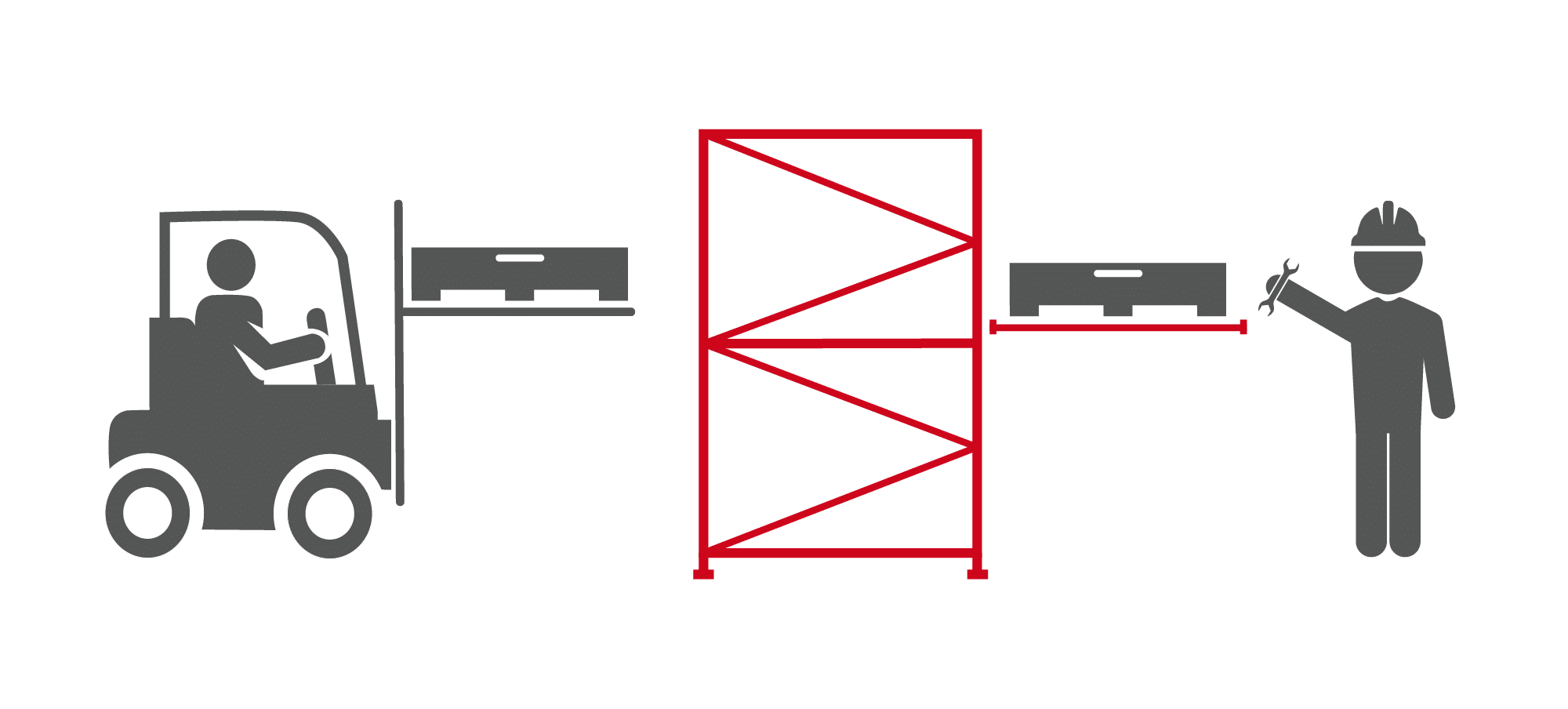

70% extension one-way

For Best Economy:

For most applications, 70% extension gives sufficientaccess to all your goods

100% extension one-way

For Maximum Access:

If you have small items at the back of the shelf or if you need to use an overhead crane for loading and picking, 100% extension makes life much easier!

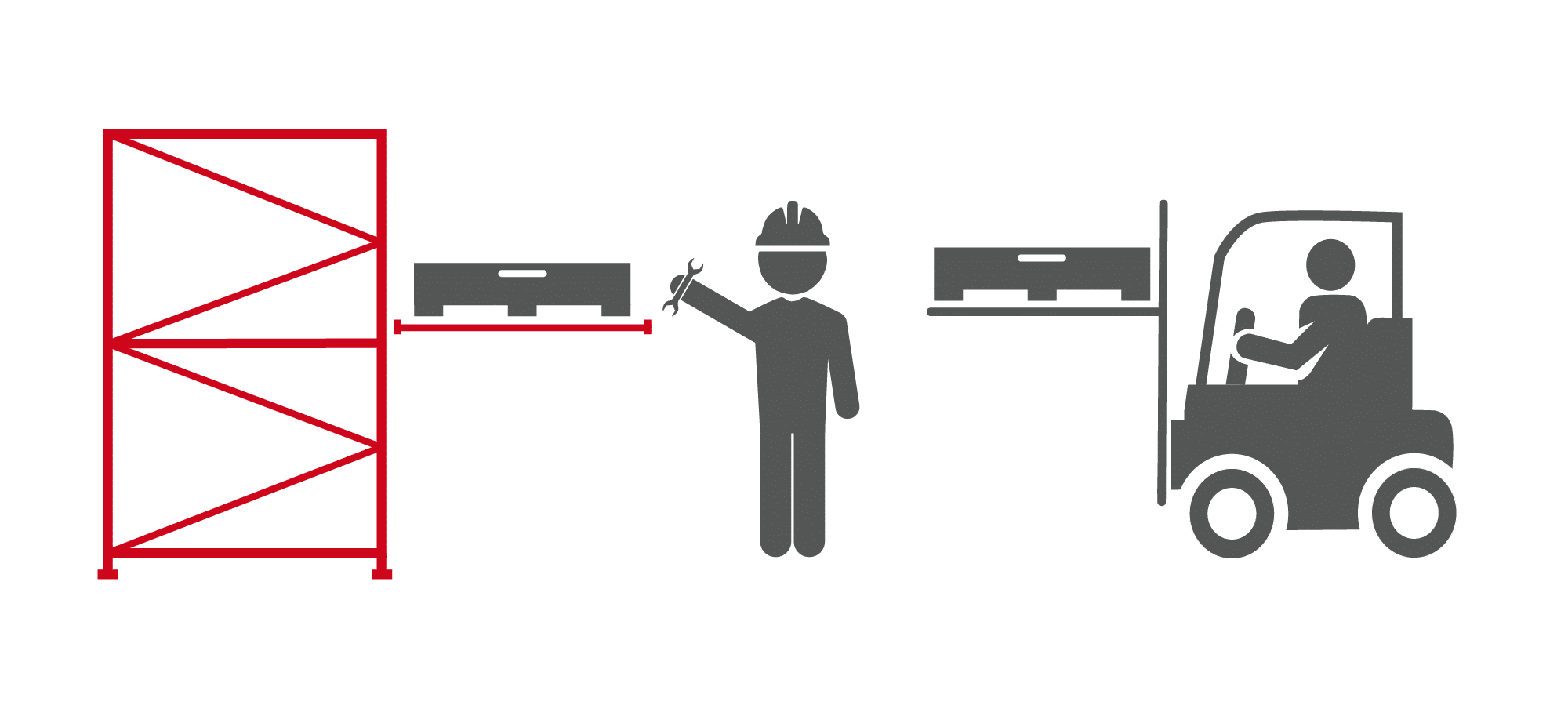

70% extension two-way

For Access Both sides:

With shelves that can be pulled out in either direction, you have the possibility of operators at separate work positions accessing the same stores, or at an assembly station one side can be used for picking and the other for restocking.

Important Safety Information

- – The pallet racking must be bolted to the floor (see manufactures instructions).

- – Rear cross beam must be bolted to the pallet racking uprights (minimum dimension M8).

- – The pull-out unit must be bolted to the rear cross-beam with the fitting kit provided.

- – Each pair of cross beams must have load capacity according to table on next page.

- – Only one pull-out unit in each section (pair of cross beams) may be pulled out at a time.

- – With using pull-out units in different levels of one rack only in one level

- a pull-out unit be pulled-out at the same time.

- – See separate notice for maximu m evenly distributed loading weight per pull-out unit

- – Directly after using the pull-out unit, it must be pushed back – check that it’s locked!